Process - Mechanical

XRG Precision Engineering provides process, mechanical, and piping engineering support for industrial projects.

Process, Mechanical & Piping Capabilities

Heat & mass balances

Pump flow studies and hydraulic calculations

Pump selection/sizing and system optimization

Heat exchanger selection/sizing

Piping design and pressure vessel design support

Pipe stress analysis and code-compliant design support

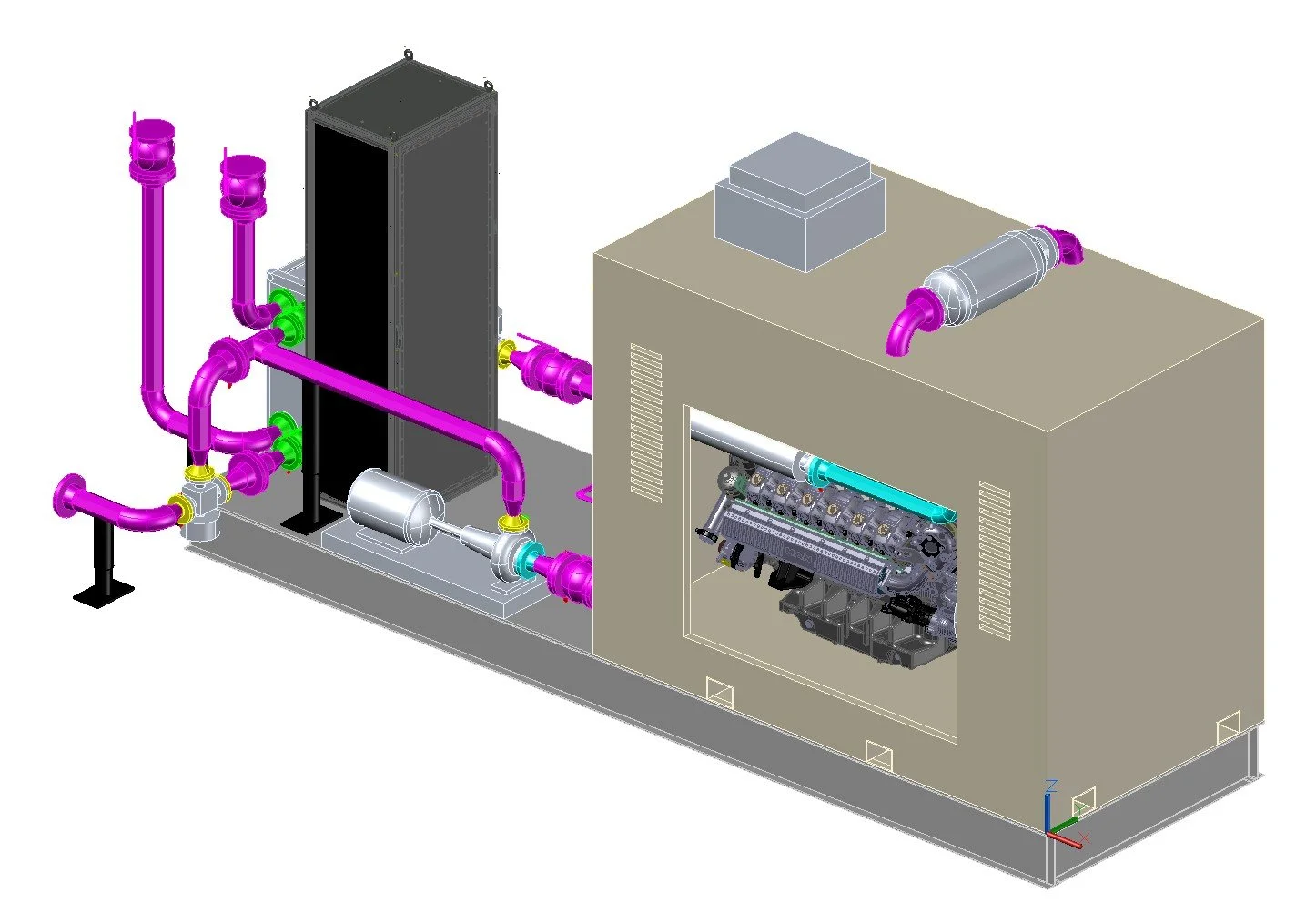

Mechanical Skid Packaging

Engineering and packaging of complete equipment skids, including:

Complete Process Engineering

Complete equipment specifications and procurement support

Mechanical design, skid layout, and fabrication-ready documentation

Packaged Cogen Units, Pump & Heat Exchanger Skids

Structural engineering

Electrical and controls integration

Detailed 3D Modeling

We create high-precision 3D models of equipment and assemblies using industry-standard tools including AutoCAD Plant 3D, Fusion 360, and SOLIDOWORKS—supporting design development, fabrication, and field integration.

Pressure Vessel Engineering

XRG Precision Engineering supports detailed pressure vessel engineering services, including design to the ASME Boiler and Pressure Vessel Code (BPVC)—Section I and Section VIII (Divisions 1 and 2). Capabilities include design-by-rule and design-by-analysis using COMPRESS and Fusion 360, and end-to-end support through procurement and fabrication for small- to medium-scale pressure vessels.